Remilk has been hitting the headlines consistently in recent months: following a $120 million oversubscribed Series B round this January, the Israeli foodtech team announced plans to construct what will reportedly be the world’s largest full-scale precision fermentation facility in Denmark.

If that wasn’t enough, just this month Remilk revealed a groundbreaking development in its journey, securing GRAS status and allowing the sale of its non-animal, real-dairy products in the USA.

It was definitely time for us to catch up with CEO Aviv Wolff, who tells us all about plans for the future and why Remilk plans to work with dairy companies, not against them.

Why did you start this company?

I have always been enthralled with problem-solving, and distilling complex challenges into clear opportunities. In my mid-twenties, I launched several social initiatives and was COO of a cyber-security start-up, but I felt something was missing. I knew I wanted to be able to wake up in the morning to work that was meaningful, generating positive change in our world, and was thinking about realistic ways to make that happen.

“I knew I wanted to be able to wake up in the morning to work that was meaningful”

As I dived deep and started learning more and more disturbing facts about our current food systems, it was clear to me that addressing the urgency of protecting the planet and ensuring a stable supply of nourishing food to its growing population was going to take more than the environmentally driven dietary changes of a few.

We would need to drive massive industrial change to make the impact meaningful. That’s how my Remilk journey began.

Why are you hoping to work with existing dairy manufacturers rather than compete with them?

We see ourselves as partners and facilitators for dairy manufacturers worldwide, as demonstrated by the fact that some of our earliest investors come from the dairy world. Dairy manufacturers have a wealth of knowledge and experience and are best positioned to understand consumers’ needs and preferences.

“We see ourselves as partners and facilitators for dairy manufacturers worldwide”

We feel that working closely together with them is our best route to provide new offerings to consumers and ultimately to transform the dairy world in the alt protein space.

What is your current and planned product portfolio?

We are engaged with dozens of food and beverage companies, including some of the world’s most popular brands, helping them prepare for the future of dairy by offering them new products for their portfolio. These consumer brands are working on crafting recipes made with Remilk and each has their own unique focus based on a deep understanding of their consumers and their needs.

What is the timing for Remilk’s build-out of the facility?

The new facility will sit on more than 750,000 square feet of acquired land and we anticipate starting to build out this facility by the end of 2022.

Once build-out is done, how soon will it begin to produce its non-dairy product?

Remilk has already started high-volume production in several locations around the world. The Danish facility will be our first fully owned facility and production at this facility, the largest of its kind in the world, will begin as soon as the build-out is complete.

Is the plan to offer its end product for B2B food companies?

Yes, we are already engaged with dozens of food companies who recognize the value of our protein which can be seamlessly integrated into various dairy products. Remilk’s animal-free milk protein enables them to offer the same favorite foods – minus the lactose, cholesterol, and hormone residues, and with a fraction of the environmental impact and zero harm to animals

How are Remilk’s products developed?

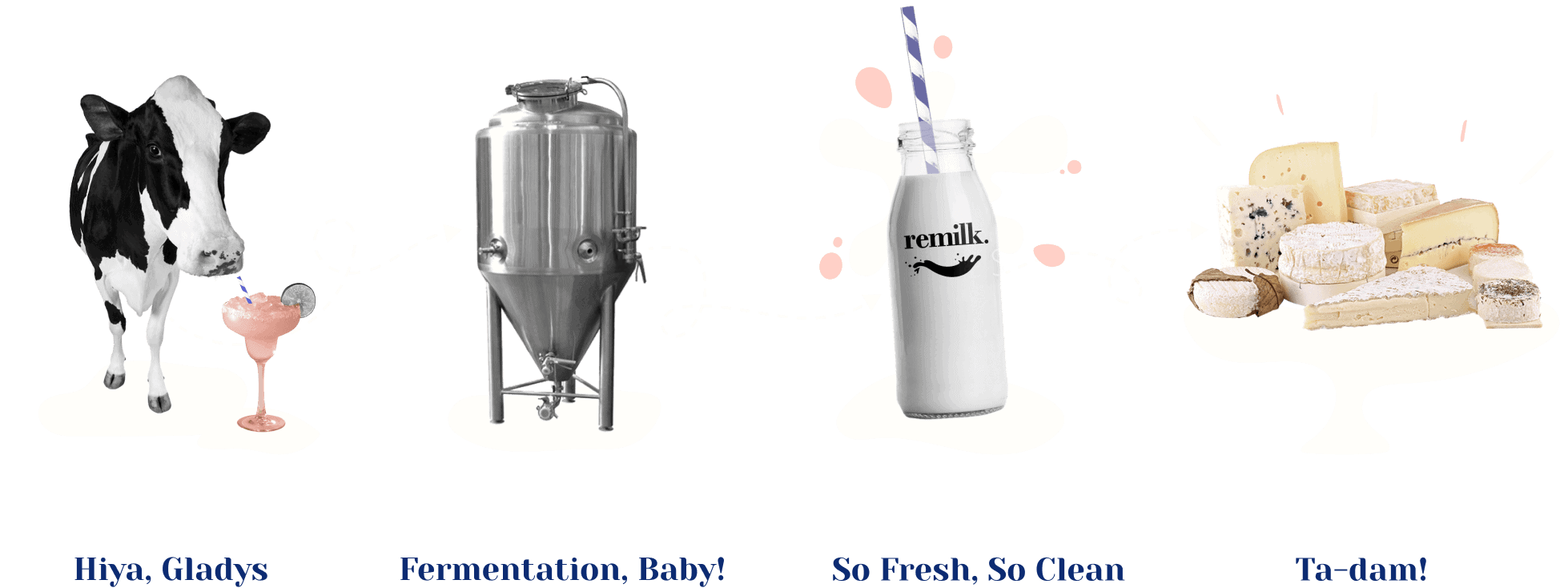

Nature provides a recipe for producing dairy. The patented Remilk process started with an understanding of the genetic properties of cow milk – essentially identifying which gene is responsible for the production of the protein that makes cow’s milk, cow’s milk.

“Nature provides a recipe for producing dairy”

We replicate the gene and add it to yeast, like the one that has been used in home kitchens and food manufacturing for hundreds of years. Once in the yeast, the “milk-protein-making” gene acts like a manual and instructs the yeast how to produce the protein in a highly efficient way.

Next is fermentation, used for centuries to create staple foods such as beer and sourdough. In a process called precision-fermentation, the yeast is placed inside large fermenters, where it rapidly multiplies and produces a non-animal milk protein that can be used in dairy products traditionally made with cow-derived milk proteins – but without a single animal cell. The final step involves the purification and drying of the protein, at which point it’s ready for use.

Why did you put your first full-scale fermentation site in Denmark?

After an extensive search, we selected Kalundborg, Denmark as the site for our first full-scale fermentation facility because of the location’s strategic advantage and powerful approach to industrial sustainability.

“Denmark is a world leader in its sustainability efforts and achievements.”

Denmark is a world leader in its sustainability efforts and achievements. When considering total power consumption, about 80% of the energy mix in the grid comes from green power sources including wind, solar and hydro.

The strategic cooperation and support we received from the city and the Danish government helped us throughout the process. And finally, the location will provide access to a deep pool of local talent.

What is unique about Kalundborg?

Kalundborg’s Symbiosis project is a pioneering industrial ecosystem with transformational economic and environmental results. Within the network, byproducts of one company become resources for another. Industry giants such as Novo Nordisk, Novozymes, and Chr. Hansen are already a part of this unique ecosystem, and we feel honored to join them in this groundbreaking project.

What are your plans over the coming years, including expansions and new markets?

We now know we must cease our dependence on animals as sources of food and nutrition. Looking forward, humankind must reimagine sources of high-quality protein to ensure that generations to come have a stable, reliable flow of nutritious foods that are sustainably sourced.

“We now know we must cease our dependence on animals as sources of food and nutrition”

For us, that means driving transformational change throughout the dairy industry. In the near term, this means building the world’s largest precision fermentation facility of its kind and working with GPG companies to bring delicious non-animal dairy products to consumers across the U.S.