Researchers at the University of Tokyo have developed a bioreactor that mimics a circulatory system, improving the production of cultivated meat by ensuring even nutrient and oxygen delivery to tissues. This new approach, published in Trends in Biotechnology, allows the creation of over 10 grams of chicken muscle tissue, addressing key challenges in scaling up cultivated meat production.

Hollow fibers for nutrient delivery

“We’re using semipermeable hollow fibers, which mimic blood vessels in their ability to deliver nutrients to the tissues,” explains senior author Shoji Takeuchi. These fibers, commonly used in medical applications such as dialysis, can now be adapted for biofabricating tissues. By precisely arranging the hollow fibers, the bioreactor ensures that nutrients and oxygen are uniformly distributed, preventing necrosis in thicker tissues, a major limitation in traditional tissue engineering.

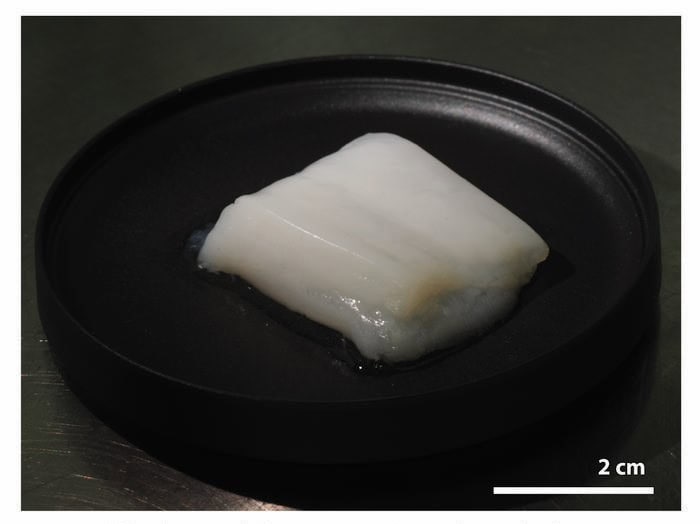

The research team demonstrated the success of their system by biofabricating centimeter-scale chicken skeletal muscle tissues using a Hollow Fiber Bioreactor (HFB) with 50 hollow fibers. They then scaled up the system, producing a 10-gram piece of whole-cut chicken meat using 1,125 hollow fibers. This innovation could improve not only texture but also flavor, making cultivated meat more comparable to conventional meat.

Accelerating commercial viability

“Cultured meat offers a sustainable, ethical alternative to conventional meat. Our technology enables the production of structured meat with improved texture and flavor, potentially accelerating its commercial viability,” Takeuchi says.

Beyond food production, the technology could have further applications in regenerative medicine and biohybrid robotics, where it could support the development of functional tissues and even organs. However, there are still challenges to overcome, including improving oxygen delivery in larger tissues, automating fiber removal, and transitioning to food-safe materials.

Takeuchi continues, “We overcame the challenge of achieving perfusion across thick tissues by arranging hollow fibers with microscale precision. The next steps include improving the mechanical properties of the tissue and adapting the technology for other applications such as organ fabrication.”