University of Alberta researchers have developed pea inks with better shape-holding features using plasma — the fourth state of matter — making them suitable for 3D-printed food applications.

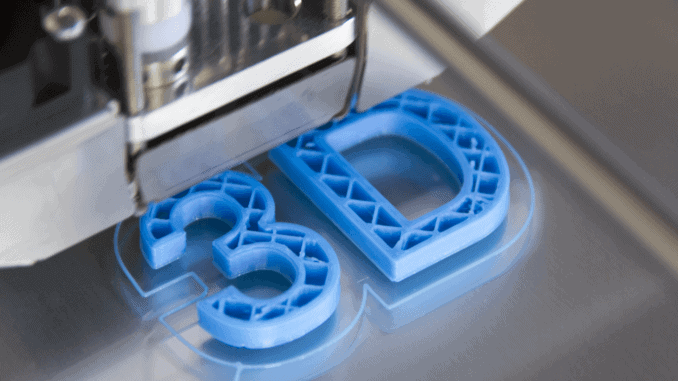

3D extrusion printing allows the creation of plant-based foods with customizable shapes, flavours, textures and nutritional profiles. But, pea protein, a hypoallergenic, low-cost source available from Canadian prairie legume crops, is generally unsuitable for 3D printing due to its poor structural properties.

Improved 3D printability of pea protein could expand its use in price convenient plant-based meat and cheese — alternatives much needed to transition to more sustainable diets.

The cold plasma method

To address the shape challenge in 3D printing, the researchers experimented by mixing pea protein isolates with water activated with cold plasma in a method called plasma-activated microbubble water (PAMB).

The trials delivered gels with better structure retention, stability during storage, and resistance to deformation compared to pea protein mixed only with distilled water. The findings, which help pea protein hold its shape better after 3D food printing, have been published in ScienceDirect.

“The improvements were possibly due to some structural changes in proteins brought on by the PAMB water,” M.S. Roopesh, one of the authors of the paper, told the University of Alberta.

Adding value

Beyond pea proteins, sources like algae, starch from grains, and fava beans would also benefit from better structures that ultimately improve the texture of 3D-printed foods, making them more appealing to consumers, Roopesh explained.

The researchers note that additional research is needed to fully understand the influencing factors involved in the process, such as the characteristics of the air and argon gas mixes, and optimum heating and cooling temperatures. Nonetheless, the work sets the stage for broader applications of cold plasma and 3D printing technologies in producing high-quality protein sources and biomaterials, Roopesh added.

“We have the potential to really add value for crop producers and the food industry”

The project was a collaborative effort involving multiple researchers and was funded by the Natural Sciences and Engineering Research Council of Canada and Alberta Innovates. The method is now open for licensing.

“Combining novel technologies like cold plasma and 3D printing for the production of better plant protein and biomaterial gels, we have the potential to really add value for crop producers and the food industry,” Roopesh added.