CytoNest Inc., a startup from the University of Georgia, has released its first commercial product, the CytoSurge 3D fiber scaffold.

The new scaffold is an edible, fiber-based structure made from generally recognized as safe (GRAS) materials. Safe for use with living tissues, it has various applications, including cell research, biopharmaceuticals, cell therapeutics, and cultivated meat and seafood.

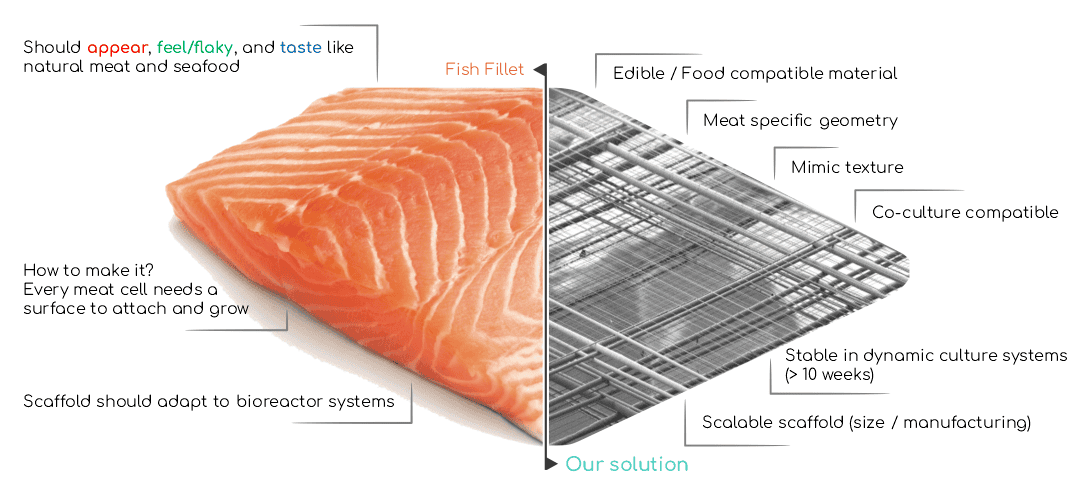

CytoSurge 3D features ultra-long strands made with CytoNest’s proprietary fiber drawing technology capable of creating ultra-long fibers that are fused or overlaid to create a multilayered, 3D scaffold for cell cultures to attach and grow.

Revolutionizing whole cuts

According to CytoNest, the scaffold mimics the natural structure of meat, the extracellular matrix (ECM), and allows for nutrient flow, a feature crucial for industrial-scale production. It supports cells’ growth three-dimensionally in high densities, making it scalable for cultivated meat and seafood production. Moreover, it’s customizable, and its production is scalable.

The developers say the technology could revolutionize the production of whole-cut products, such as fish fillets or steaks.

Collaborating for innovation

CytoNest Inc. was founded by Nataraja Yadavalli (CEO) and Sergiy Minko (CSO), a Georgia Power Professor of Fiber and Polymer Science in the College of Family and Consumer Sciences. Minko’s decade-long research culminated in optimizing the scaffolding technology and building a working prototype in 2019.

As the University of Georgia reports, Yadavalli, a postdoctoral fellow in Sergiy Minko’s lab, developed the breakthrough fiber-spinning method for creating nanofiber scaffolds. The innovation was realized during comparative research with existing commercial nanofiber fabrication technologies, which primarily use older electrospinning technology.

The development process involved significant contributions from postdoctoral fellows, graduate students, and undergraduates. For example, Alex Tokarev, a postdoctoral fellow, made a major breakthrough in developing the new nanofiber spinning technology.

Later, through the Innovation Gateway’s NSF I-Corps program, Minko and Yadavalli investigated the commercial potential of the scaffold developed with the new spinning method. After two sessions of its customer-discovery program, they decided to start CytoNest Inc.

Grants from the Georgia Research Alliance, the Good Food Institute, and the US Department of Agriculture supported the product launch. These grants facilitated access to necessary tools, lab space, equipment, and services for the product’s development and eventual market release.

“Many graduate and undergraduate students were also involved and helped in these developments. These combined efforts and successful developments were very inspiring,” Minko told Brandon Ward from the University of Georgia.

He added, “It is impossible to underestimate the help and support of UGA, NSF I-Corp, Innovation Gateway, and the Georgia Research Alliance, which were critical to establishing and shaping the startup company.”